We’ll begin with normal issues when designing a sheet metal parts, after which you can move ahead to best style practices for laser chopping, bending, and generating holes.

Surface area treatment method is an important part of the sheet metal processing approach since it prevents rust and enhances the appearance with the product.

Deep drawing is really a course of action utilized to create hollow cylindrical shapes. It really works by placing sheet metal about a die and pressing the metal blank into the die cavity using a punch, resulting in a hollow cylindrical condition without having reduction within the thickness on the sheet metal.

Suitable application: Larger workpieces made from softer metals, in which tolerance and end is vital. Can deliver heavy burrs.

Samples of sheet metal elements include the iron shell of an auto plus some stainless-steel kitchen area utensils.

Hemming is no less than a two phase approach where by a piece of sheet metal is bent and bottomed out right into a V-die, then removed and placed into a flattening die to flatten the hem. Hemming differs from the curl because the Uncooked edge is uncovered.

For those who’re like most website homeowners, The thought of putting in a fresh roof at the time and currently being finished is quite attractive. With as many as a sixty-12 months existence expectancy, metal roofing really should be the last roof you’ll ever install.

In the first design, the sheet metal demanded two individual bending processes. Nevertheless, during the improved design, the sheet metal only wants 1 bending method to variety the two sides at the same time.

On common, metal roofing may also help reduce utility payments by twenty%. Combining Those people financial savings in excess of thirty yrs can cover Nearly 50 % the cost of your new metal roof. Eco Friendly

To mitigate these troubles, I have a pattern of revising the mould immediately after Every single check and generating modifications as desired, taking into consideration both angle rebound and radius rebound. Needless to say, a talented technician might make changes efficiently, and they will inform the designer of the necessary adjustments.

As shown during the figure underneath, This is a simplified illustration of a complex sheet metal bending component. The bending sequence includes to start with bending the higher facet and after that bending the best aspect.

Capacity boundaries for every system Each technique has limits that make combining various processes a requirement.

Building a bend having a spherical or greater hole accommodates a higher bending tolerance and assures good assembly from the section.

This short article seems in the sheet metal forming procedure, how it works, wherever it is employed, and its Added benefits and disadvantages. We also Look into the sub-processes used to fabricate areas with the metal sheets.

Alisan Porter Then & Now!

Alisan Porter Then & Now! Destiny’s Child Then & Now!

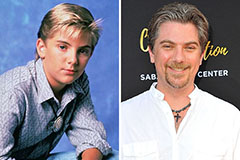

Destiny’s Child Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now!